Why Preventive Maintenance (PM)?

Preventive maintenance (PM) is “a routine for periodically inspecting” with the goal of “noticing small problems and fixing them before major ones develop.”

Like us, your machines needs to daily cleaning and maintenances. These daily cleaning and maintenance are very important for your machines. If you think of the daily maintenance of the human body as sleep, you can notice of the daily maintenances how important for the machines.

However, every person needs holidays on certain days a week so that they start the new week with renewed and recovered. Just like this, your machines need weekly maintenance. In this way, more detailed machine cleaning and maintenance are performed which you do not look / control in daily maintenance.

You can think of monthly machine maintenance as your annual leave. We return to our business with more renewed and new ideas on our annual leave and this increases our morale extraordinarily. Your machines do not need such a holiday, maybe all they need is to replace the oil, clean the control panel, check the sockets.

In fact, all your maintenance needs are so simple, ordinary and usual. Only we ignore it and therefore we often encounter unexpected breakdowns.

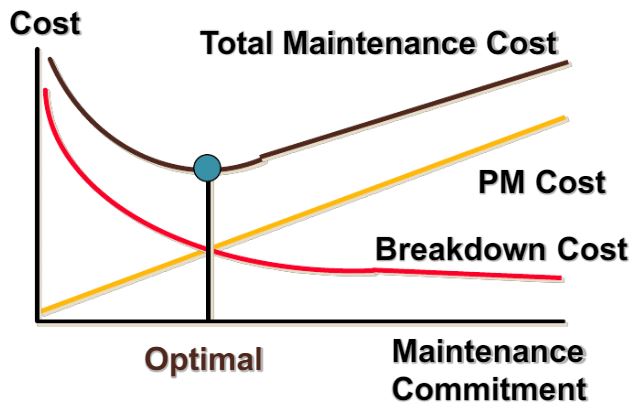

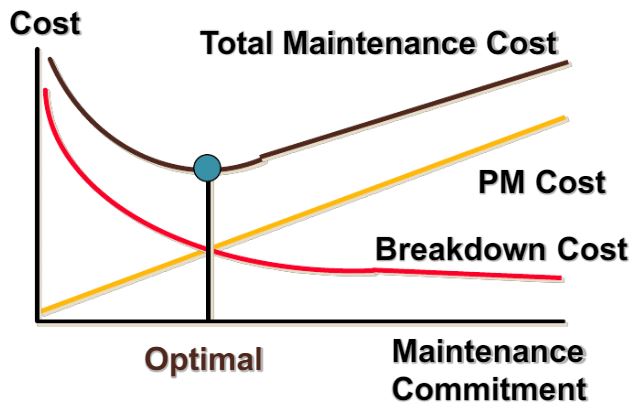

Of course, it is not possible for machines that are maintained regularly to not fail at all. However, as you can see in the figure below, keeping it at OPTIMAL level is important for both cost and production.

Main Types of Maintenance

Planned preventive maintenance (PPM), more commonly referred to as simply planned maintenance (PM) or scheduled maintenance, is any variety of scheduled maintenance to an object or item of equipment. Specifically, planned maintenance is a scheduled service visit carried out by a competent and suitable agent, to ensure that an item of equipment is operating correctly and to therefore avoid any unscheduled breakdown and downtime.

Planned maintenance is preplanned, and can be date-based or based on equipment running hours.

Predictive maintenance techniques are designed to help determine the condition of in-service equipment in order to estimate when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted. Thus, it is regarded as condition-based maintenance carried out as suggested by estimations of the degradation state of an item.

The main promise of predictive maintenance is to allow convenient scheduling of corrective maintenance, and to prevent unexpected equipment failures. The key is “the right infor equipment lifetime, increased plant safety, fewer accidents with negative impact on environment, and optimized spare parts handling.

Condition-based maintenance (CBM), shortly described, is maintenance when need arises. Albeit chronologically much older, It is considered one section or practice inside the broader and newer predictive maintenance field, where new AI technologies and connectivity abilities are put to action and where the acronym CBM is more often used to describe ‘condition Based Monitoring’ rather than the maintenance itself. CBM maintenance is performed after one or more indicators show that equipment is going to fail or that equipment performance is deteriorating.